The way that drinking water and wastewater systems pay for energy improvements in the United States is changing – including for small drinking water systems (serving 10,000 or fewer people). As has often been mentioned on the EFC’s blog, the days of huge federal grants for construction of water and wastewater systems are long past. Since an energy improvement is a kind of capital improvement, there are many ways to pay for such projects: cash savings (e.g. through a utility’s capital improvement fund); loans (state revolving fund loans or bank loans); issuing bonds (if you are a local government entity); internal energy revolving funds; and more. But coming up with the initial capital through one of the aforementioned means can be challenging.

One growing method for funding (as well as studying, designing, and building) energy management projects at water systems is Energy Savings Performance Contracting (ESPC).

A local government owned water system undertaking an Energy Savings Performance Contract would be an example of a Public Private Partnership (PPP). A non-governmental entity that is still a water system (for-profit company, non-profit company, co-op, etc.) would also be able to look at an ESPC arrangement. The ESPC approach has been more heavily used in the past for other kinds of projects, but now appears to be gaining some momentum for water systems, including small water systems.

The EFC has identified several communities throughout the U.S. that have begun ESPC work for their water systems, ranging from small systems like Big Lake, TX (service population 2,963) to Ada, OK (service population 17, 112). Energy savings initiatives at these locations have included projects for the water distribution and wastewater collection systems, water treatment plants, and wastewater treatment plants, such as replacing old, energy inefficient pump motors; installing variable frequency drives (VFD’s) on pump motors; heating, ventilating, and air conditioning (HVAC) and lighting improvements; and even installing advanced meter reading (AMR) or advanced metering infrastructure (AMI) projects as a means of addressing non-revenue water issues, which has an energy management component to it.

Background: Energy and Water Usage in the United States

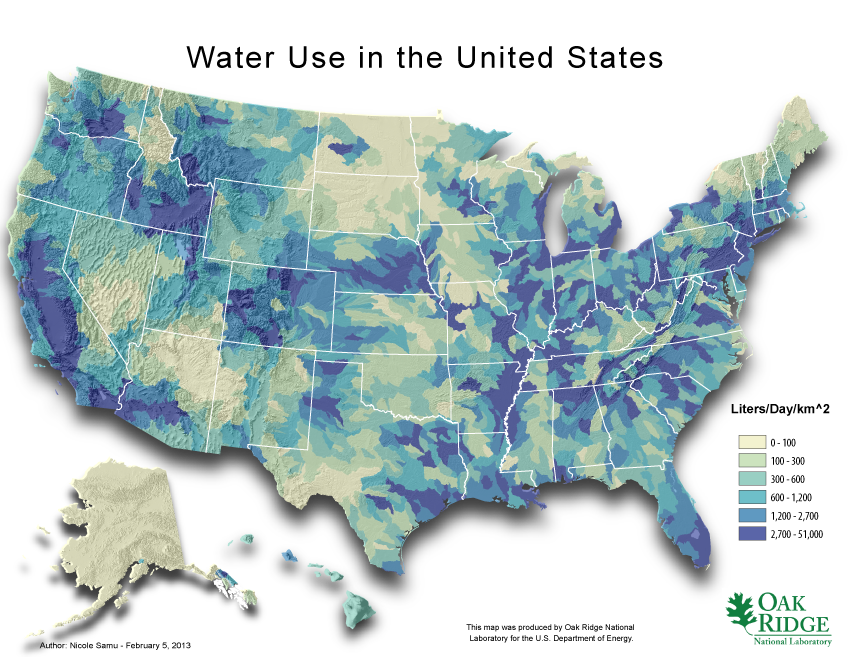

We are a thirsty country, both for water and for electricity! According to the U.S. Geological Survey and the Pacific Institute, total water use in the United States in 2010 was approximately 350 billion gallons per day, including both freshwater and saline water usage. Figure 2 shows water usage intensity in liters per day per square kilometer, courtesy of the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL):

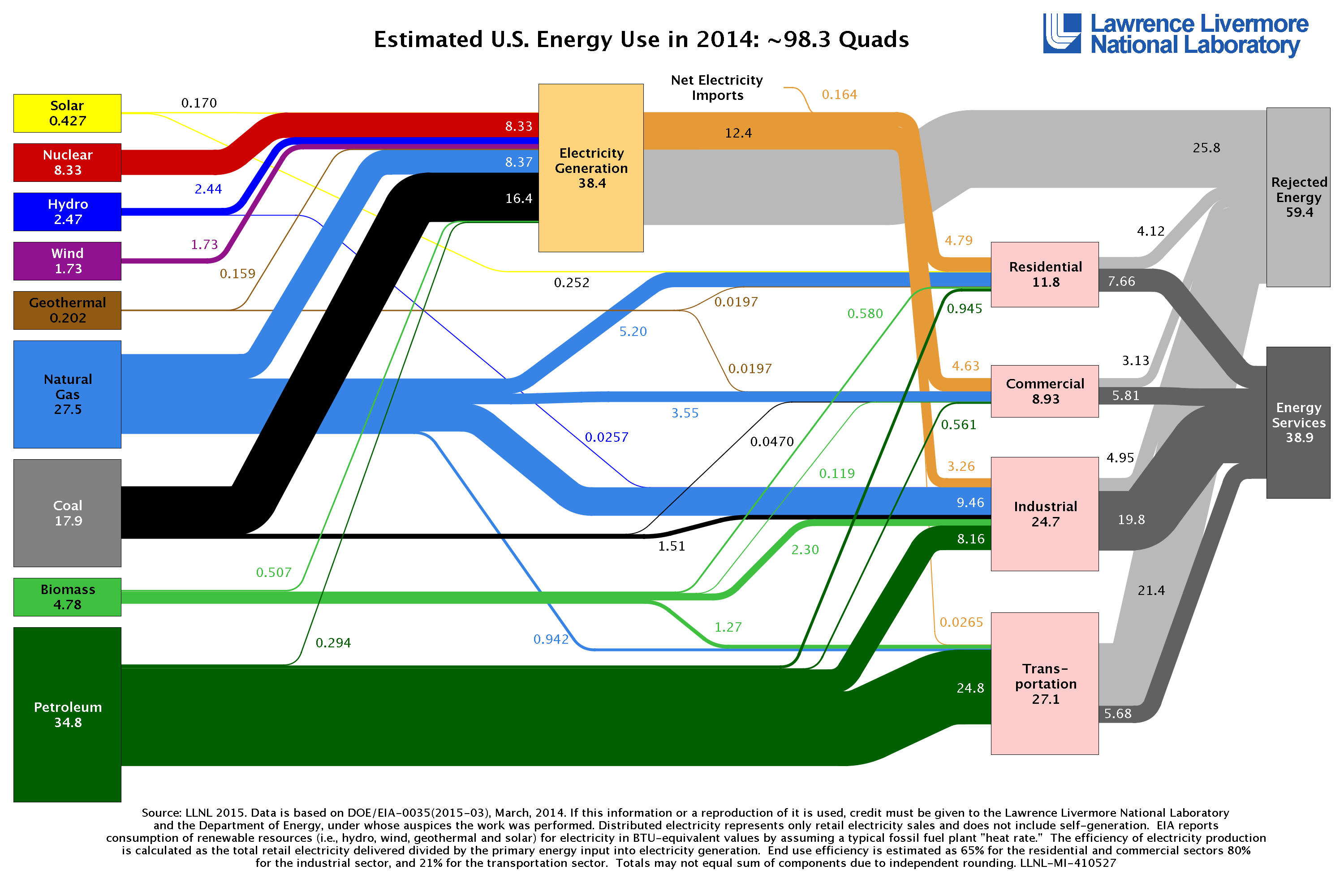

We are also a very energy intensive society. According to the U.S. Energy Information Administration (EIA), in May of 2015, the United States generated 321,906 mWh (megawatt-hours) of electricity, and retail sales comprised 285,707 mWh. On an annual basis, the U.S. produced 98.3 quads of energy in 2014, according to U.S. DOE’s Lawrence Livermore National Laboratory (LLNL). One quad of energy equals one quadrillion BTU’s (British thermal units); and 98.3 quads is approximately 28.8 trillion kWh (kilowatt-hours). The general breakdown of the annual generation and end-use of energy in the USA can be seen in Figure 3.

Putting these two subjects together, delivering water and wastewater services to consumers represents a very significant percentage of national electricity consumption. The U.S. Environmental Protection Agency (EPA), through its “Make the Drops-to-Watts Connection” initiative on water and energy efficiency, states that:

Delivering water and wastewater services is also an energy-intensive effort, as the water is treated, pumped to our homes and businesses, then pumped to wastewater facilities to be treated again. EPA estimates 3-4 percent of national electricity consumption, equivalent to approximately 56 billion kilowatt-hours (kWh), or $4 billion, is used in providing drinking water and wastewater services each year. Water and wastewater utilities are typically the largest consumers of energy in municipalities, often accounting for 30-40 percent of total energy consumed. Pursuing energy efficiency at our water sector systems can significantly reduce operating costs, while mitigating the effects of climate change.

There is opportunity in the water and wastewater utility sectors to implement energy management projects, potentially saving a great deal of money for the utility. For many water systems, the electric (or energy) bill is one of the largest operating expenses regularly incurred, and it is one of the most controllable operating expenses a water system will have. Some projects may be low-to-no capital process changes, but other projects (e.g. replacing all of your old pump motors with highly energy efficient ones) are more capital intensive. So how do we pay for it? And how can we use Energy Savings Performance Contracting for this purpose?

How Energy Savings Performance Contracting Works

Energy Savings Performance Contracting for a water or wastewater system is a means of moving ahead with energy management projects even when the system is hard-pressed to come up with the capital on its own. But it is also more than that: the Energy Services Company (ESCO) that you will work with can provide you with a range of capabilities, including studying your current energy usage, proposing projects you may choose to undertake, and designing, building, and financing those projects. At the 30,000 feet view of things, you then pay back these energy improvements out of the energy savings you have reaped, such as with reduced electricity bills from new, more energy efficient pump motors. In practice, of course, the ESPC model is a bit more complicated than that, and with variations in different states around the country, and with different ESCO’s and their respective business models. For more on the ESPC model in general, you can check out DOE’s ESPC web page, as well as EPA’s ESPC page, or the National Association of Energy Service Companies (NAESCO) web page (which also lists several dozen prominent ESCO firms around the USA).

Before we look further at some details of how ESPC works, it’s important to emphasize that, if you are a local or state government entity, the enabling legislation (as to whether and how you can engage in ESPC for your water system) varies considerably from state to state. Usually your state energy office will be able to give you the relevant legal guidelines, and they may be able to provide you with considerable administrative support as well. If you do not know how to contact your state energy office, you may want to look at the website of the National Association of State Energy Officials (NASEO) to find them. Also, you may want to look at the interactive map and database to check on the status of ESPC enabling legislation in each state across the country, created by ORNL.

While the exact details will vary of how a given Energy Savings Performance Contract will work, here is a common model the EFC has seen:

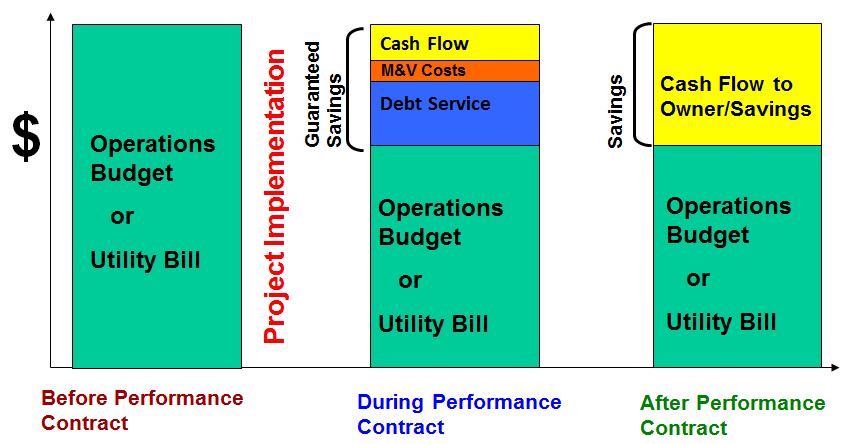

An ESCO makes a proposal to a water system and designs a package of energy cost reduction measures. In many cases, it may be a requirement by the state that a local government owned utility must issue a Request for Proposals (RFP) and go through a process to select an ESCO, as is the case here in North Carolina. But once the ESCO has been selected, they will install / implement the energy conservation measures (ECM), and guarantee the energy cost savings for the utility. Financing is arranged (more on that in a moment), and the water system repays the financing out of the revenue stream created by the energy cost savings. Terms of the contracts may be 10, 15, or even 20 years. It will typically be important to the ESCO when studying the water system’s situation to be able to find enough “low hanging fruit,” i.e. energy projects that will have relatively short payback periods, to balance out any “high hanging fruit” in the mix of projects, so that overall payback period is doable within the contract period. Figure 3 below shows the before, during, and after snapshots of costs and savings.

It is not uncommon for there to be no less than three contracts to be signed by the water system:

- The energy services contract with the ESCO allows them to study, design, build, and implement the energy savings projects. Typically, an investment grade energy audit (IGA) will be required.

- The measurement and verification (M&V) contract allows a third-party firm to measure and verify the energy savings from the projects, helping to arbitrate any disagreements between the water system and the ESCO. (In some cases, we have seen the M&V done by the ESCO themselves, though for some that might raise a conflict of interest question.)

- The financing contract is often done through a financing company / arrangement. For example, one small water system utility we have talked to issued municipal general obligation bonds and placed the bonds with a bank. Even after paying the ESCO with the money generated by the bond issuance (and the ESCO is doing the M&V work), and paying the coupon on the bond to the bondholder (the bank), as well as ultimately having to repay the bonds themselves to the bondholder, the water system is still experiencing $100,000 less in energy costs annually, across the life of the 15 year contract, a number which will go much higher each year once the contract ends. Their improvements include new, more energy efficient pump motors and VFD’s for the water distribution and wastewater collection systems, and numerous new pump motors, blowers, and other equipment at the water treatment plant and the wastewater treatment plant, and the implementation of advanced meter reading (AMR) infrastructure (which has both non-revenue water benefits to claw back that lost revenue from more accurate meters, as well as energy savings from reducing pumping and truck fleet operations requirements) for a $5 million contract.

Benefits and Pitfalls of Energy Savings Performance Contracting

The benefits of Energy Savings Performance Contracting can include:

- Solutions to infrastructure and operational needs

- Guaranteed results = minimal risk for the water system

- Reduced operating / utility costs

- Best life cycle cost, not just the lowest price

- Turnkey project development and implementation

- Saves the water system time and provides solutions

Thus the ESPC set of arrangements provides the water system with not only energy cost reductions, but also with capital, expertise, manpower, and guaranteed savings.

However, there can be pitfalls as well to the ESPC approach. They can include challenges such as:

- Failure of water system owner to perform due diligence

- Failure to properly understand all contracts

- Overly optimistic expectations / promises by the ESCO

- Poor project specifications

- Failure to do an IGA (Investment Grade Audit)

- Failure to do proper M&V (Measurement and Verification)

- Failure to properly understand state-level regulations for ESPC, if you are a local government owned water system.

- Staff time must be allocated by the water system to see process through across time.

Tips for Success

If an Energy Savings Performance is to be successful, some keys to success can include:

- Assemble all needed stakeholders

- Create a data packet for the project(s)

- Issue an RFP (if required/desired – your state energy office may have a template RFP)

- Evaluate responses to the RFP (select an ESCO)

- Perform an IGA

- Negotiate all needed contracts (ESCO, M&V, finance)

- For government agencies: get approval from the appropriate government agency

- Seek out free support from your state energy office (which may include many offerings, including approved lists of ESCO firms, M&V firms, energy auditors, etc.)

While the ESPC approach may not be for everyone, it is a growing method of financing and supporting energy management projects for organizations of all kinds, including small water systems. It provides access to capital, expertise, manpower, and typically guarantees you a given amount of energy savings. And it allows you a new tool in your financial toolkit to help you figure out how to make those energy costs of your system to “contract” into ever smaller amounts!