by Harmony Bouley

In the wake of the declining textile, tobacco, and furniture industries, North Carolina’s agricultural sector has remained robust. North Carolina’s agricultural sector, which has production levels that have historically ranked among the top ten agricultural states nationally, continues to be a boon for the state’s economic prosperity. Farmers across the state grow over 80 different crops and types of livestock and employ 16 percent of the state’s workforce. Good stewardship of the resources necessary to provide this bounty is essential to the long term growth of the industry.

Huge Potential for Growth

In 2014, the General Assembly funded the NC Food Processing and Manufacturing Initiative, which aims to expand agriculturally-based businesses. As part of this initiative, the College of Agriculture and Life Sciences at North Carolina State University and the North Carolina Department of Agriculture and Consumer Services jointly conducted an economic feasibility study. This study found that expanding agriculturally-based businesses through food processing could add as much as $10.3 billion to the state’s economic output by 2020. This expansion would bring the state’s agricultural economic impact to $100 billion, representing a 22 percent growth in the agricultural sector’s contribution to the state economy. Based on these findings, Governor Pat McCrory created the NC Food Processing and Manufacturing Task Force, which is charged with implementing a plan to execute this growth.

Increased agricultural production and processing, however, likely leads to increased water consumption and wastewater discharge. What does this anticipated growth in food processing and manufacturing in North Carolina mean for municipal water and wastewater operators? What are the expected impacts of food processors on wastewater streams?

Impact on Municipal Water

Food processing includes any mechanism that takes an agricultural good and adds value to it. Processors add value to agricultural goods when they process them into items such as fruit jams, wine, baked goods, beer, salsas, etc. Enormous amounts of wastewater may be generated through food processing. While effluent characteristics and treatment requirements vary across the industry, two commonly monitored metrics of wastewater quality in food processing are biochemical oxygen demand (BOD) and total suspended solids (TSS).

BOD is a metric for how much dissolved oxygen is required for biological organisms to break down the organic material present in the water. In general, BOD from meat processing is much higher than from processing fruits or vegetables. TSS is another water quality metric which represents the weight of solids captured by filtering. For instance, the primary TSS from a brewery are grain solids. At high levels of concentration, both BOD and TSS can contribute to lower oxygen levels in water and cause different types of water pollution such as eutrophication.

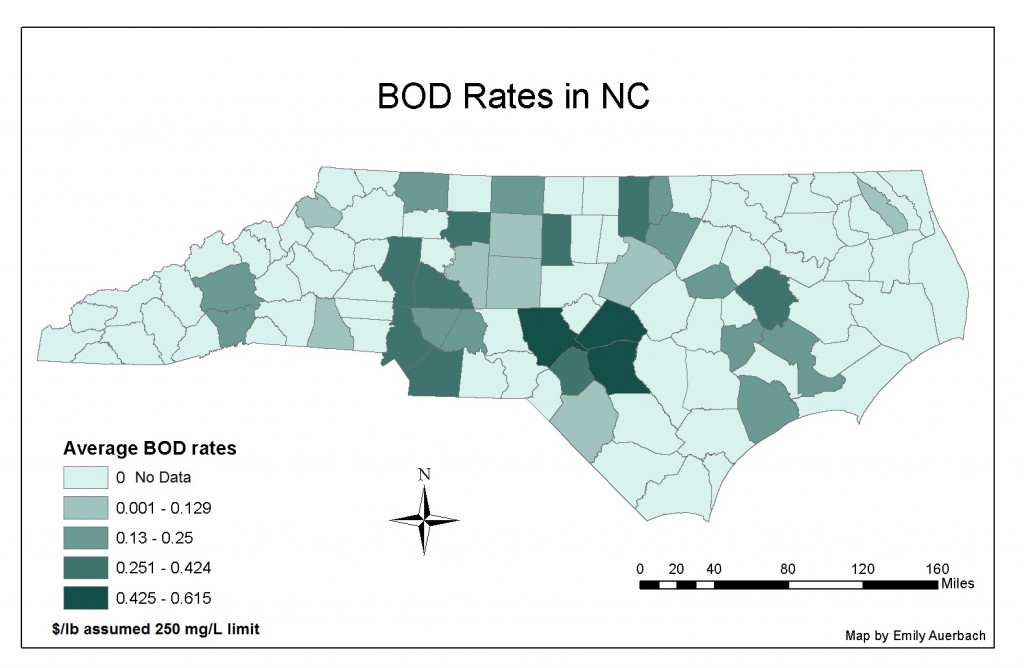

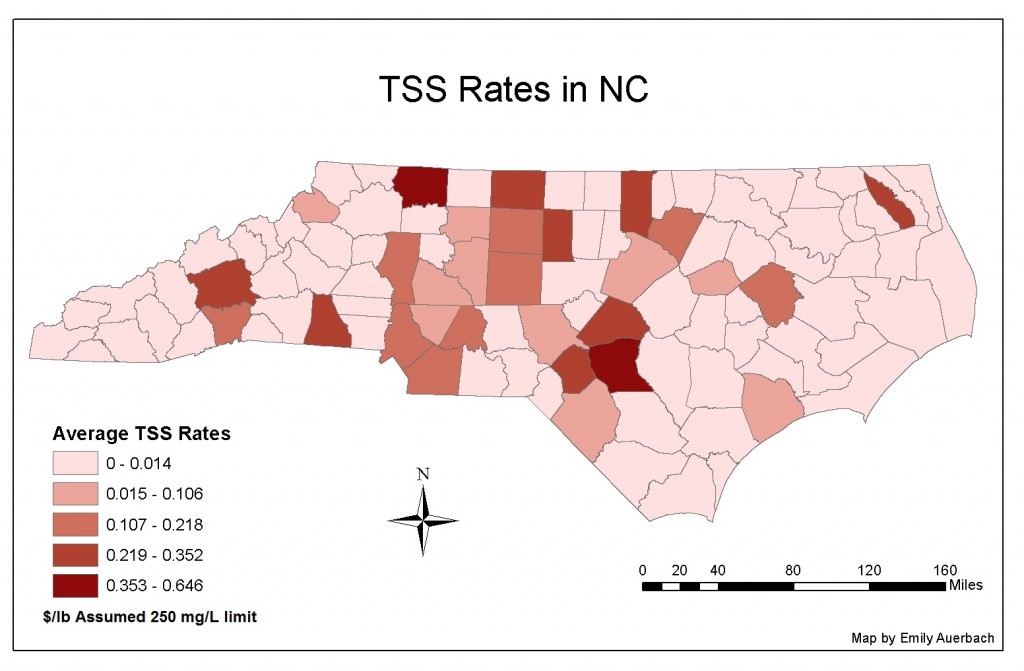

The EFC conducted a small survey in partnership with the NC Food Processing and Manufacturing Task Force to collect wastewater rates for 68 different municipalities. The survey aimed to determine whether and how municipalities charge for high levels of BOD (Figure 1) and TSS (Figure 2).

For example, if the City of Durham’s local limits for BOD and TSS are 250 mg/L and 180 mg/L respectively and a local brewery has a BOD of 150 mg/L and TSS of 100 mg/l in its effluents, the brewery will not have to pay for its BOD and TSS discharges.

The lowest limit for BOD and TSS of the surveyed municipalities was 200 mg/L with a corresponding $.119 and $.071 charge per pound. The highest limit for BOD and TSS of the surveyed municipalities reached 400mg/L with a $.04 charge for both effluents.

Due to the many factors that go into the decision of where to site a food processing operation, it is unlikely that the existence of BOD and TSS rates would alter an operator’s choice of location. The existence of rates can, however, impact the design of a new food processing facility, incentivizing the processor to reduce BOD and TSS to minimize costs. Water authorities that establish appropriate rates for these pollutants encourage newcomers to their territories to institute good wastewater management technologies and practices. These rates also ensure that the authorities themselves have the funding needed to adequately treat discharges from food processors.

Harmony Bouley is a student research assistant at the Environmental Finance Center. She is majoring in Environmental Sciences at UNC Chapel Hill and is interested in how local entities finance environmental services.

3 Responses to “Managing Water Impacts of NC Food Processing”

Al D

Thank you for this article. Do you have any related info on what local water suppliers are doing in areas with many meat processing facilities? I guess this would apply more for those with direct, rather than indirect discharges.

Kendall Singleton

Thanks for the informative article, Harmony. It would be interesting to see what the rate threshold is that may motivate behavior change. I imagine it depends greatly on the size of the business in question, but you may see some patterns emerge.

Spencer Nelson

Definitely something to keep track of. Thanks for posting.